The semiconductor industry, once a niche field confined to laboratories and factories, now underpins every aspect of modern civilization. From smartphones and laptops to autonomous vehicles and military satellites, semiconductors are embedded in the systems that drive global productivity, innovation, and security. In 2024, the global semiconductor market reached a valuation of $627.6 billion, reflecting an annual growth rate of 19.1%. Projections by Precedence Research suggest the market could surpass $1.2 trillion by 2034, driven by technological demand and geopolitical investment. This article explores the intricacies of the semiconductor supply chain, the evolving market landscape, and the strategic power plays redefining global influence.

The Anatomy of the Semiconductor Supply Chain

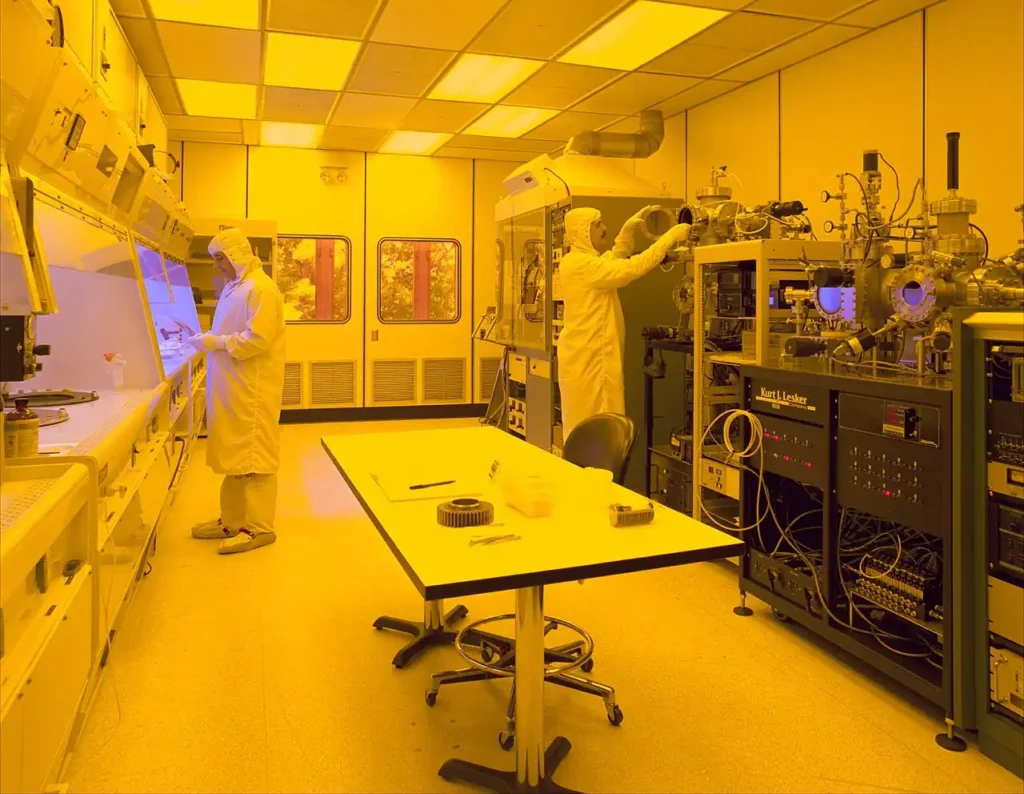

The semiconductor supply chain is not linear but rather a vast, globally distributed ecosystem involving design, fabrication, packaging, testing, and integration. The earliest phase begins with design firms—known as “fabless” companies—such as Nvidia, AMD, and Qualcomm. These companies use sophisticated Electronic Design Automation (EDA) tools, often provided by American firms like Cadence and Synopsys, to create chip architectures tailored to specific applications.

The manufacturing—or fabrication—stage is capital intensive and technologically complex. Foundries like Taiwan Semiconductor Manufacturing Company (TSMC), Samsung Electronics, and Intel are the central players here. A single advanced fabrication plant, or “fab,” costs upward of $20 billion to build and takes several years to become operational. These fabs manufacture chips using photolithography equipment, most notably produced by ASML of the Netherlands, whose EUV (Extreme Ultraviolet) lithography machines are essential for producing chips smaller than 7 nanometers.

After fabrication, semiconductors are cut, assembled, and packaged—a process often conducted in countries like Malaysia, Vietnam, and the Philippines. The chips are then tested for functionality and durability before being shipped to electronics manufacturers worldwide. This layered and geographically interdependent system is what makes the semiconductor industry both powerful and perilously vulnerable.

Concentration and Fragility: A Geopolitical Flashpoint

The global semiconductor supply chain is highly concentrated in a few regions. According to Boston Consulting Group, over 90% of the world’s most advanced chips are produced by TSMC in Taiwan. This makes the island not only an economic linchpin but also a geopolitical flashpoint, especially amid rising tensions between China and the United States. Taiwan’s strategic importance has prompted both economic alliances and military posturing in the Indo-Pacific region.

Meanwhile, the United States controls much of the upstream intellectual property in chip design and manufacturing tools, while Japan dominates specialty materials such as photoresists and etching gases. South Korea plays a crucial role in both memory chip production and display integration. Together, these players form a supply chain that, while efficient, is extremely sensitive to disruption.

Natural disasters, trade wars, pandemics, and cyberattacks can all cascade through this interconnected web. The COVID-19 pandemic exposed this vulnerability starkly, as chip shortages crippled industries from automotive to consumer electronics. According to a 2021 report by Goldman Sachs, semiconductors were embedded in roughly 169 different U.S. industries. Any bottleneck in this sector has wide-reaching economic consequences.

U.S. Strategy and the CHIPS Act

Recognizing the strategic importance of semiconductors, the United States has moved aggressively to rebuild its domestic manufacturing capacity. In August 2022, President Joe Biden signed the CHIPS and Science Act into law, allocating $52.7 billion in subsidies to support semiconductor manufacturing and research. Additional tax incentives are projected to leverage over $200 billion in private sector investments.

Leading American companies such as Intel, Micron, and GlobalFoundries have announced plans for new fabs in Arizona, Ohio, and New York. Intel’s upcoming facility in Ohio is expected to be one of the largest semiconductor sites in the world, with a projected investment of $100 billion over the next decade. While these efforts are unlikely to overturn Asia’s dominance immediately, they signal a long-term strategic pivot.

In parallel, export controls have been placed on advanced chip technology destined for China. These include restrictions on high-end GPUs and AI accelerators, directly impacting companies like Nvidia. The goal is to slow China’s access to leading-edge capabilities, though critics warn this could accelerate China’s domestic innovation in response.

China’s Drive for Semiconductor Self-Reliance

China imports more semiconductors by value than oil, spending over $350 billion annually. In response to U.S. export restrictions and broader trade tensions, the Chinese government has made semiconductor independence a national priority. Under the “Made in China 2025” initiative and subsequent five-year plans, the country has committed hundreds of billions of dollars toward domestic chip production.

Firms such as SMIC (Semiconductor Manufacturing International Corporation) are central to this effort. While SMIC remains generations behind leaders like TSMC in producing advanced nodes (3nm or below), it has made significant progress in mature nodes (28nm and up). In 2023, reports emerged that Chinese researchers had succeeded in producing 7nm chips using older DUV lithography equipment, bypassing the need for EUV technology.

While skepticism remains about the commercial scalability of such feats, they underscore China’s determination to reduce dependency. At the same time, China continues to court foreign talent and acquire semiconductor-related IP through mergers, partnerships, and poaching—strategies that have drawn the scrutiny of Western security agencies.

The European Chips Act and Global Competition

Europe, too, has joined the semiconductor race. In 2022, the European Commission proposed the European Chips Act, aiming to mobilize over €43 billion in public and private investments. The objective is to double Europe’s share of global chip production to 20% by 2030. Key players in the European ecosystem include STMicroelectronics, Infineon Technologies, and ASML.

Europe’s strategy emphasizes resilience through diversification, rather than vertical integration. Several countries have partnered with Intel, TSMC, and Samsung to establish new manufacturing facilities on European soil. In Germany, Intel is investing more than €30 billion to build two advanced fabs, with construction expected to begin by 2025. France, Italy, and the Netherlands are also exploring opportunities to expand semiconductor R&D, particularly in niche areas such as automotive chips and photonics.

Raw Materials and the Global Mineral Chain

The semiconductor supply chain is not limited to design and manufacturing. It begins far earlier—with raw materials such as silicon, rare earth elements, cobalt, tungsten, and gallium. These materials are often mined in geopolitically unstable regions or controlled by a few countries. China, for instance, supplies over 80% of the world’s rare earth elements and more than 90% of refined gallium, prompting concerns about supply manipulation.

In 2023, Beijing imposed export restrictions on gallium and germanium, critical materials for chipmaking and fiber optics, in retaliation for Western export controls. This move demonstrated how mineral dependency can be leveraged as a geopolitical tool. In response, the U.S., EU, and Japan have all launched initiatives to secure alternative sources of strategic materials, including partnerships with Australia, Canada, and several African nations.

The Role of Private Sector Giants

Corporate players are not just responding to national policy—they are helping shape it. TSMC remains the most important chip manufacturer globally, producing more than 60% of the world’s semiconductors and over 90% of the most advanced chips. In 2023, TSMC’s revenue exceeded $75 billion, with nearly half generated from U.S.-based clients such as Apple, AMD, and Nvidia.

Samsung Electronics, the South Korean giant, is the largest producer of memory chips and also competes in logic chips. It is expanding its foundry operations in Texas and planning a $17 billion fab in Taylor, expected to come online by 2026. Meanwhile, ASML in the Netherlands continues to hold a monopoly on EUV lithography, with each machine costing around $150 million. Only a few dozen of these machines are made each year, and they are critical to the advancement of semiconductor miniaturization.

U.S.-based Nvidia has emerged as a major player in AI hardware, with its GPUs and AI accelerators like the H100 becoming essential to large-scale model training and data center operations. Restrictions on Nvidia’s high-end chips to China have prompted global buyers to stockpile, pushing up prices and creating artificial scarcity.

Innovation and the Future of Semiconductor Architecture

Looking ahead, the architecture of semiconductors is undergoing transformation. Traditional Moore’s Law scaling is hitting physical limits, prompting a shift toward new paradigms such as chiplets, 3D stacking, and open-source designs. AMD and Intel are already using chiplet-based processors to achieve higher yields and performance efficiency. Open hardware ecosystems like RISC-V are gaining traction as flexible, customizable alternatives to proprietary instruction sets.

Quantum computing, neuromorphic chips, and silicon photonics also represent frontier technologies that could redefine computational capability. While still largely in experimental stages, these innovations are receiving increasing investment from governments, universities, and venture capital alike. The U.S. National Quantum Initiative and similar programs in China and Europe are directing billions toward quantum-compatible hardware, often using exotic semiconductor materials like indium antimonide or silicon carbide.

Conclusion: The New Silicon Diplomacy

The semiconductor industry has become the arena for 21st-century geopolitical competition. No longer just components in our gadgets, chips are now critical infrastructure—shaping national security, economic growth, and scientific leadership. From Washington and Brussels to Beijing and Taipei, the race for semiconductor supremacy is not merely about economics, but about who leads and who follows in the digital future.

Securing the semiconductor supply chain will require a multi-pronged approach: expanding domestic production, diversifying suppliers, investing in talent, and fostering international cooperation. As the industry approaches a trillion-dollar horizon, those who master the chip will shape the course of global power.